Gasket Plate With Heat Exchanger

Product Details:

- Color Silver

- Usage Industrial

- Product Type Gasket Plate With Heat Exchanger

- Size Different Size

- Click to View more

Gasket Plate With Heat Exchanger Price And Quantity

- 1290 INR/Unit

- 1 Unit

Gasket Plate With Heat Exchanger Product Specifications

- Gasket Plate With Heat Exchanger

- Silver

- Industrial

- Different Size

Gasket Plate With Heat Exchanger Trade Information

- Cash Advance (CA)

- 300 Unit Per Month

- 14 Days

- All India

Product Description

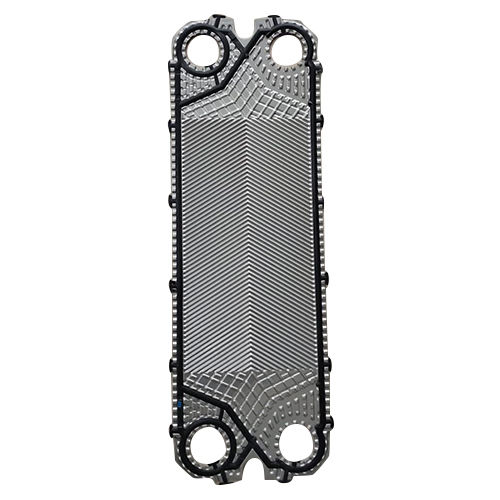

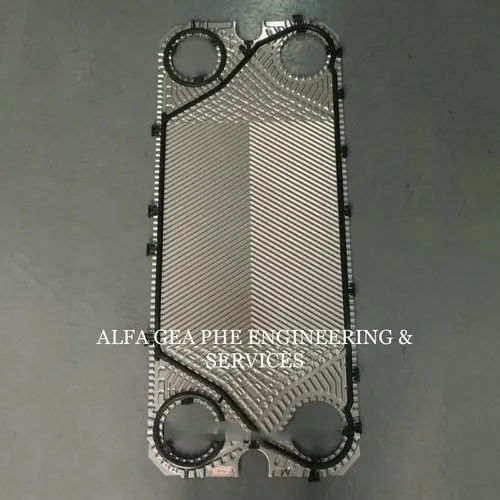

The Gasket Plate With Heat Exchanger is a reliable and efficient solution for industrial heat transfer needs. It is a high-performance heat exchanger designed to provide maximum efficiency and reliability. The heat exchanger is constructed of a durable stainless steel, making it resistant to corrosion and other environmental factors. The plates are made of a high-grade material that is designed to withstand extreme temperatures. The gasket plate is designed to fit into a variety of applications, making it a versatile and reliable solution for industrial heat transfer. The Gasket Plate With Heat Exchanger is designed to provide maximum efficiency and reliability. It is designed to provide a wide range of thermal transfer options, including air-to-air, water-to-air, and air-to-water. The design of the heat exchanger allows for the efficient transfer of heat from one medium to another, making it ideal for industrial applications. The plates are designed to be easily installed and are easy to maintain. The plates are available in different sizes to suit different applications. The Gasket Plate With Heat Exchanger is designed to provide maximum efficiency and reliability. It is designed to provide a wide range of thermal transfer options, including air-to-air, water-to-air, and air-to-water. The design of the heat exchanger allows for the efficient transfer of heat from one medium to another, making it ideal for industrial applications. The plates are designed to be easily installed and are easy to maintain. The plates are available in different sizes to suit different applications.

A gasketed plate heat exchanger PHE is a specific type of heat exchanger that consists of multiple plates with gaskets between them These gaskets create tight seals allowing two different fluids to flow on either side of the plates without mixing Heat is transferred between the fluids through the thin metal plates

Heres how a gasketed plate heat exchanger generally works

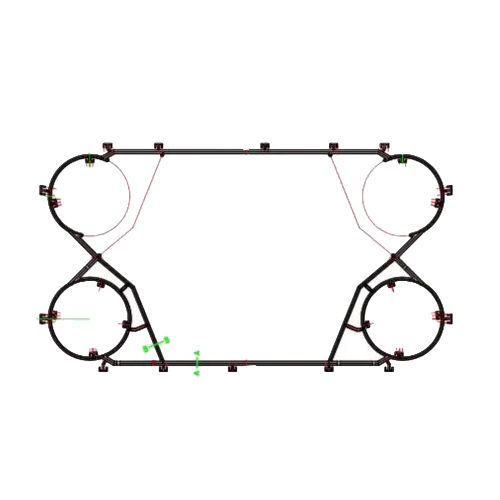

Plate Assembly The heat exchanger consists of a series of metal plates with gaskets along the edges These plates are usually made of stainless steel or other corrosionresistant materials

Fluid Flow Two different fluids often hot and cold flow through alternating channels formed by the plates The gaskets ensure that the fluids remain separate and dont mix

Heat Transfer Heat is transferred from the hot fluid to the cold fluid through the thin metal plates The large surface area of the plates enhances the efficiency of heat exchange

Gaskets The gaskets provide a seal between the plates preventing any leakage between the two fluid streams Gasket materials are chosen based on factors such as temperature pressure and the nature of the fluids

Connections Inlet and outlet ports are provided for each fluid allowing them to enter and exit the heat exchanger

Gasketed plate heat exchangers are known for their efficiency compact design and ease of maintenance They are commonly used in various industries including HVAC systems chemical processing food and beverage production and more

Regular maintenance involves checking and replacing gaskets as needed ensuring that the plates are clean and addressing any issues that may affect the performance of the heat exchanger Proper maintenance helps maintain the efficiency and reliability of the heat exchanger over time

FAQs of Gasket Plate With Heat Exchanger:

Q: What is the Gasket Plate With Heat Exchanger?

A: The Gasket Plate With Heat Exchanger is a reliable and efficient solution for industrial heat transfer needs. It is a high-performance heat exchanger designed to provide maximum efficiency and reliability.Q: What is the material used to make the Gasket Plate With Heat Exchanger?

A: The heat exchanger is constructed of a durable stainless steel, making it resistant to corrosion and other environmental factors. The plates are made of a high-grade material that is designed to withstand extreme temperatures.Q: What types of thermal transfer can the Gasket Plate With Heat Exchanger provide?

A: The Gasket Plate With Heat Exchanger is designed to provide a wide range of thermal transfer options, including air-to-air, water-to-air, and air-to-water.Q: Are the plates easy to install?

A: Yes, the plates are designed to be easily installed and are easy to maintain.Other Products in 'PHE Gasket Plate' category

GST : 07HHCPK0124F1ZT

|

ALFA GEA PHE ENGINEERING & SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese